Creating a tool for operational leads to manage manufacturing risks and optimize production.

CLIENT

Pfizer Inc.

TYPE

Manufacturing 4.0

ROLE

UX Designer

FORM

iPad OS

DURATION

Design Workshop

INDUSTRY

Life Sciences

This was an Enterprise Design Thinking Workshop that took place at a drug substance facility in Ireland.

Alongside another designer, architects, SMEs, end users, and business stakeholders, I designed a tool that aims to mitigate risks and streamline operations associated with batch production.

Understanding the bottleneck: Batch production hiccups are reliant on Subject Matter Experts (SMEs).

Some drug substance facilities manufacture multiple batches simultaneously. In these cases, a batch takes a certain amount of time to finish and has defined timings that must be adhered to. However, if a batch runs off track/experiences a delay, then all batches before and after it must be mitigated, and their timings manipulated with their respective defined timing in order for production to continue smoothly.

Sample process area- this is where production of batches occur

Aligning stakeholders on the problem statement: Human-dependent mitigation is a risk to efficiency and focus.

Currently, the batch mitigation process is manual and depends heavily on operational leads with deep process knowledge. These individuals must determine the necessary adjustments and interventions, introducing risk for human error and inefficiencies. Since mitigation is not their primary responsibility, it also pulls focus away from their core day-to-day duties.

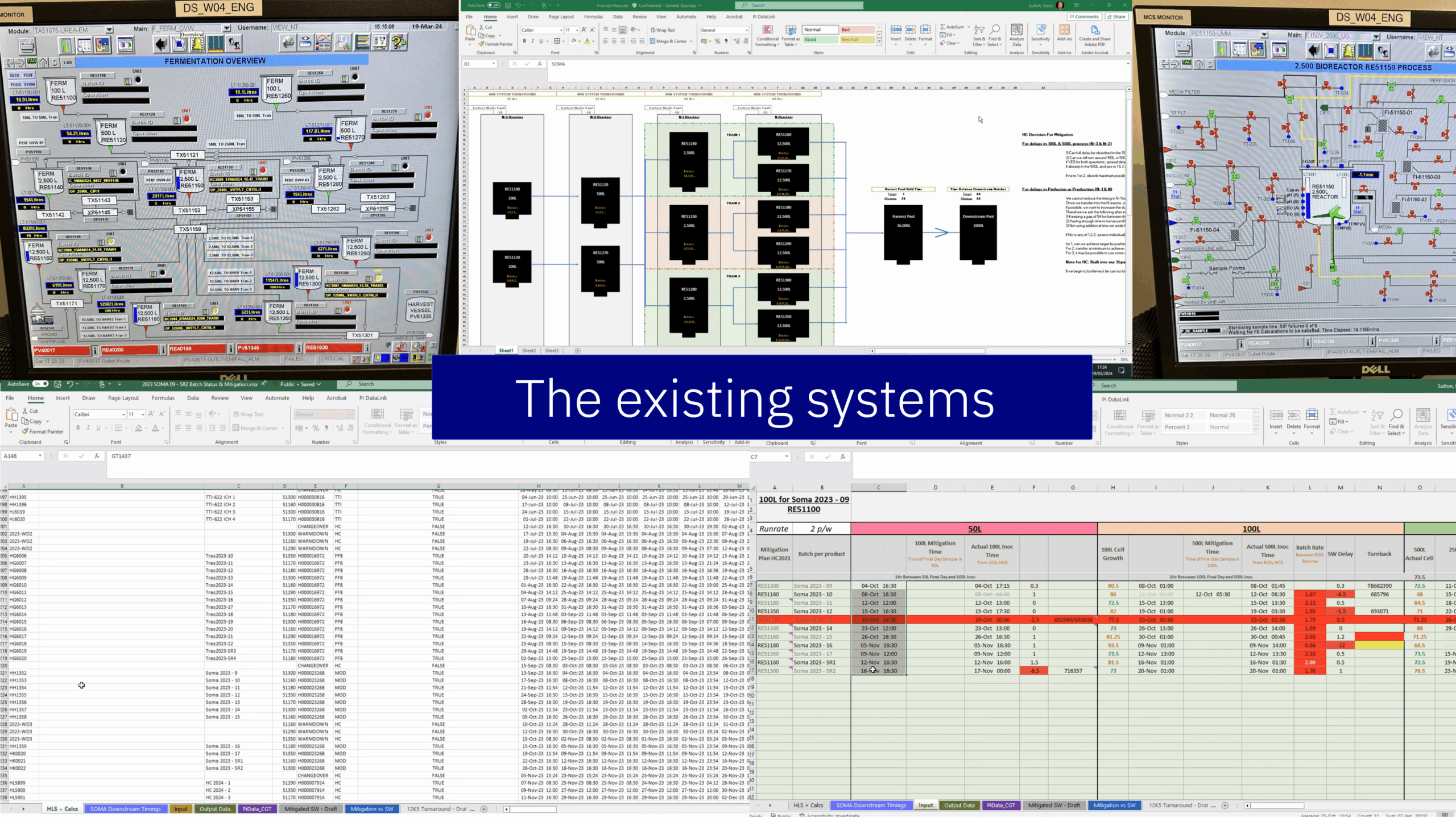

SME's have to use various disparate systems and have to perform manual calculations to calculate new batch timining.

Finalizing the design solution: An automation tool designed to streamline mitigation and empower operational leads.

By the last day of the workshop, we had facilitated multiple stakeholder alignment conversations, design reviews, architecture discussions, and business value sessions.

At last, we designed a manufacturing solution that automates the mitigation process—reducing manual effort, minimizing errors, and enabling not only operational leads but also cross-functional teams to focus on their core responsibilities with greater confidence and efficiency.

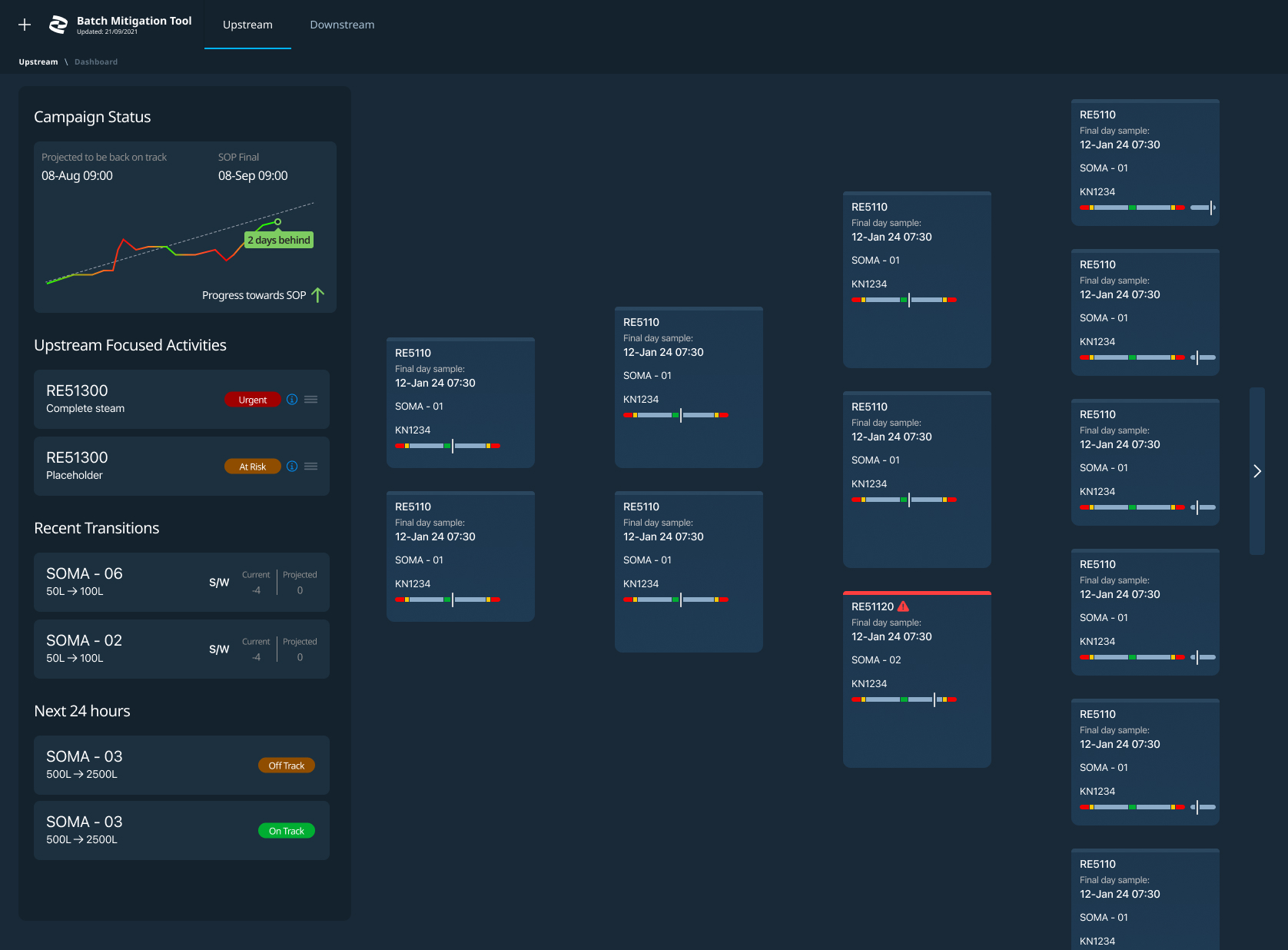

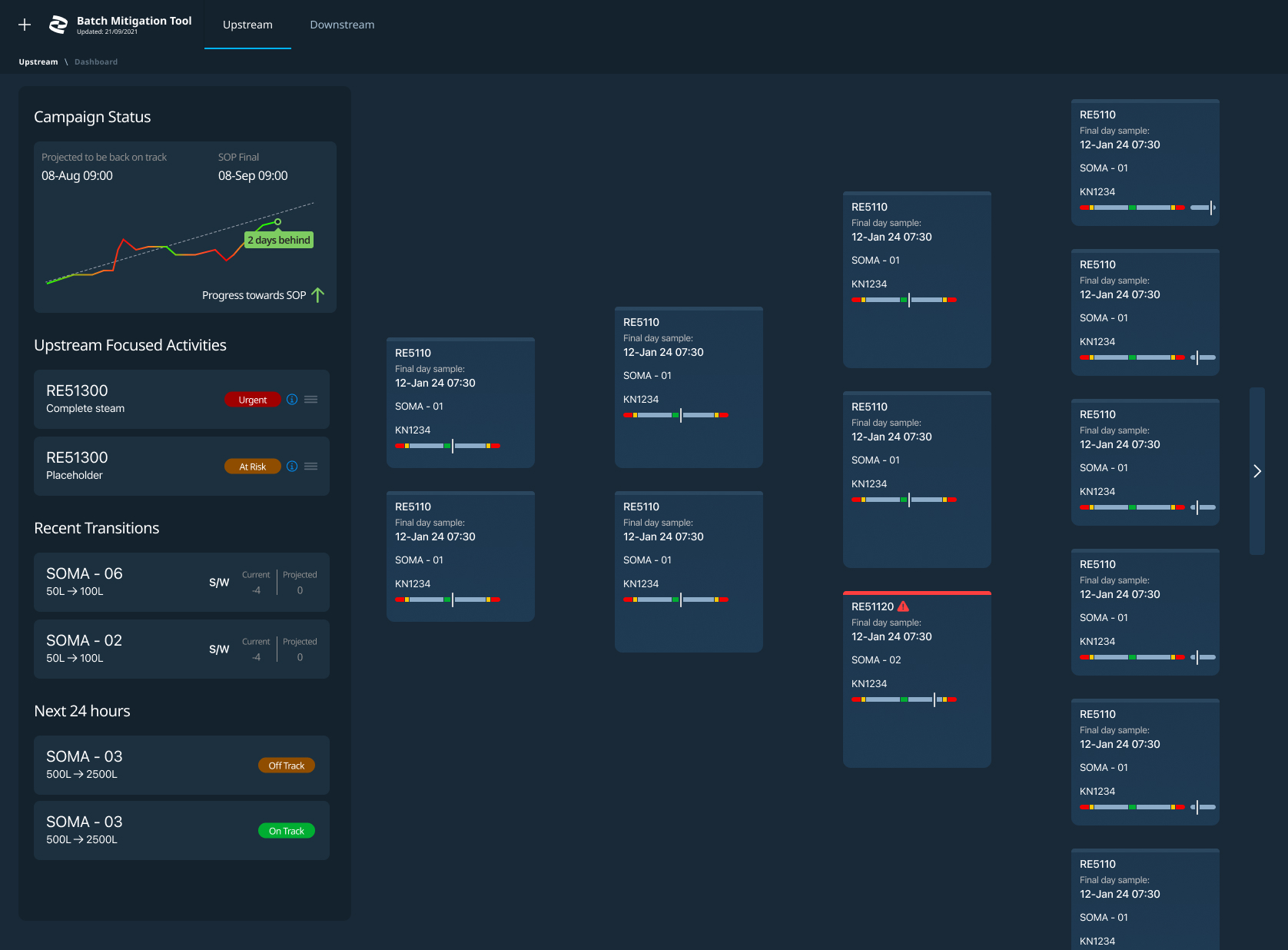

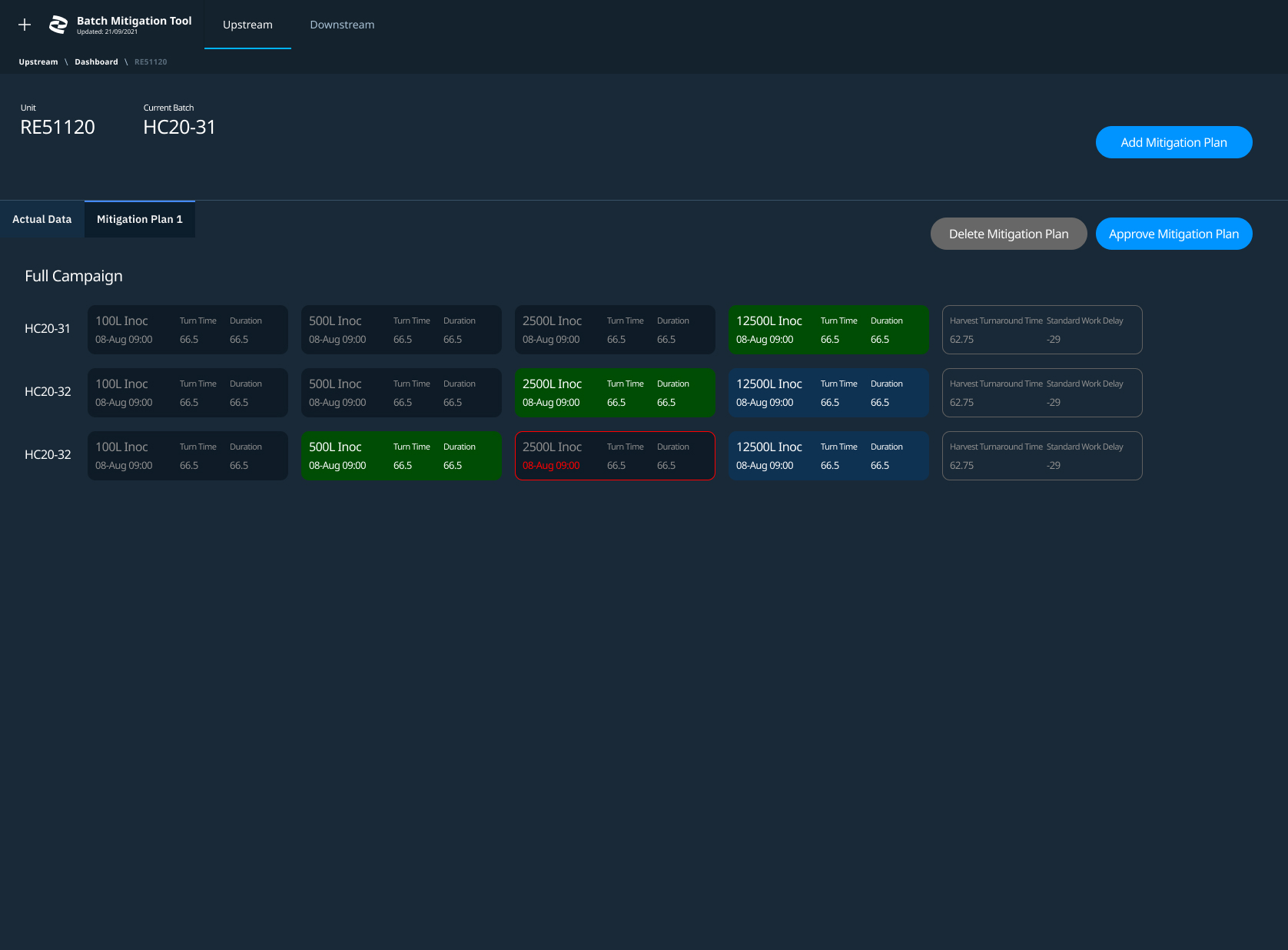

Final design solution home page - this is one screen out of multiple

A quick dive into the solution

The dashboard view decreases the speed to developing a mitigation plan from 3 to 12 hours (6 on average) to an estimated 30 minutes.

A task duration decrease of 92%.

Previously, developing a mitigation plan could take anywhere from 3 to 12 hours (averaging 6), largely due to data silos and disconnected systems. Just identifying that an issue existed could consume hours.

With the new tool, that process now takes an estimated 30 minutes—a 92% reduction in task duration.

By providing a comprehensive overview at the start of each shift, the tool informs users of standard work expectations and real-time batch status within the equipment. This enables operational leads to act faster, with clarity and confidence.

A quick dive into the solution

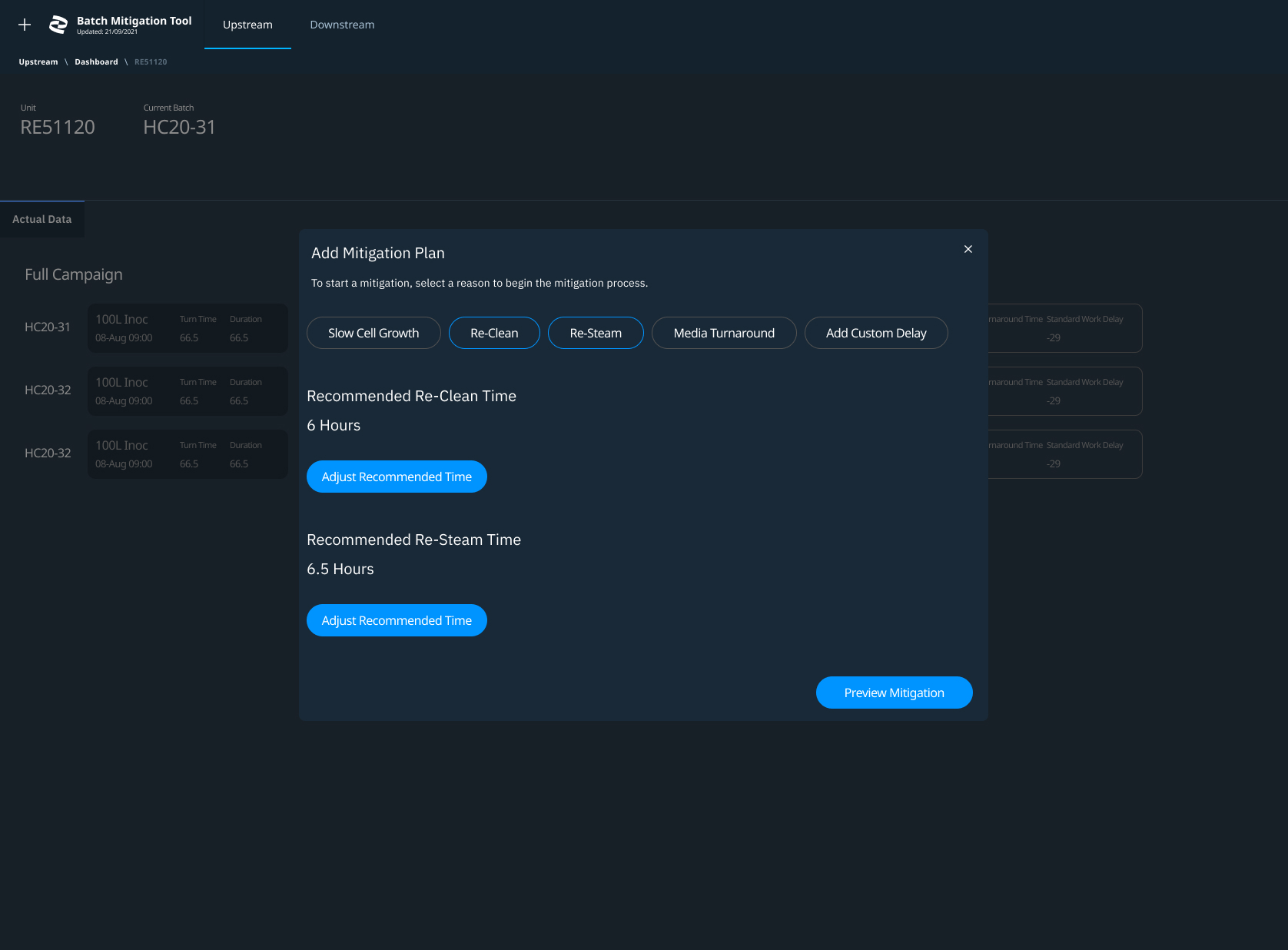

The tool improves consistency and accuracy, leading to fewer mitigation plans, less rework, and higher yields with fewer disruptions.

Plan accuracy is estimated to improve from 75% accuracy to 95% accuracy.

When a mitigation need is identified, the app can auto-generate a plan based on business rules and past data—giving users a solid starting point without needing to dig through multiple systems.

From there, users can easily adjust variables like delay time (e.g., 8 hours to 12 hours) for batches in progress or tweak start times for upcoming batches. This makes it simple to explore different scenarios and choose the best plan with confidence.

Lessons Learned

The value of being resourceful

Due to the complexity of the topic, the design lead and I were stuck for the entire first day. We didn’t understand the manufacturing process and all the important details that needed to be prevalent in our designs. We looked for alternatives and tackled this challenge through creative problem solving. Instead of the traditional workshop flow, we decided to co-design 1:1 with the SME so that we could have more focused, simplified conversations about design.

When all feels a mess, focus on the outcomes

By being outcome focused, we moved away from trying to understand the details to focusing on what we needed to deliver - designs. We used the co-design 1:1 session to help us achieve this.

Take a look at my other projects 𓀙

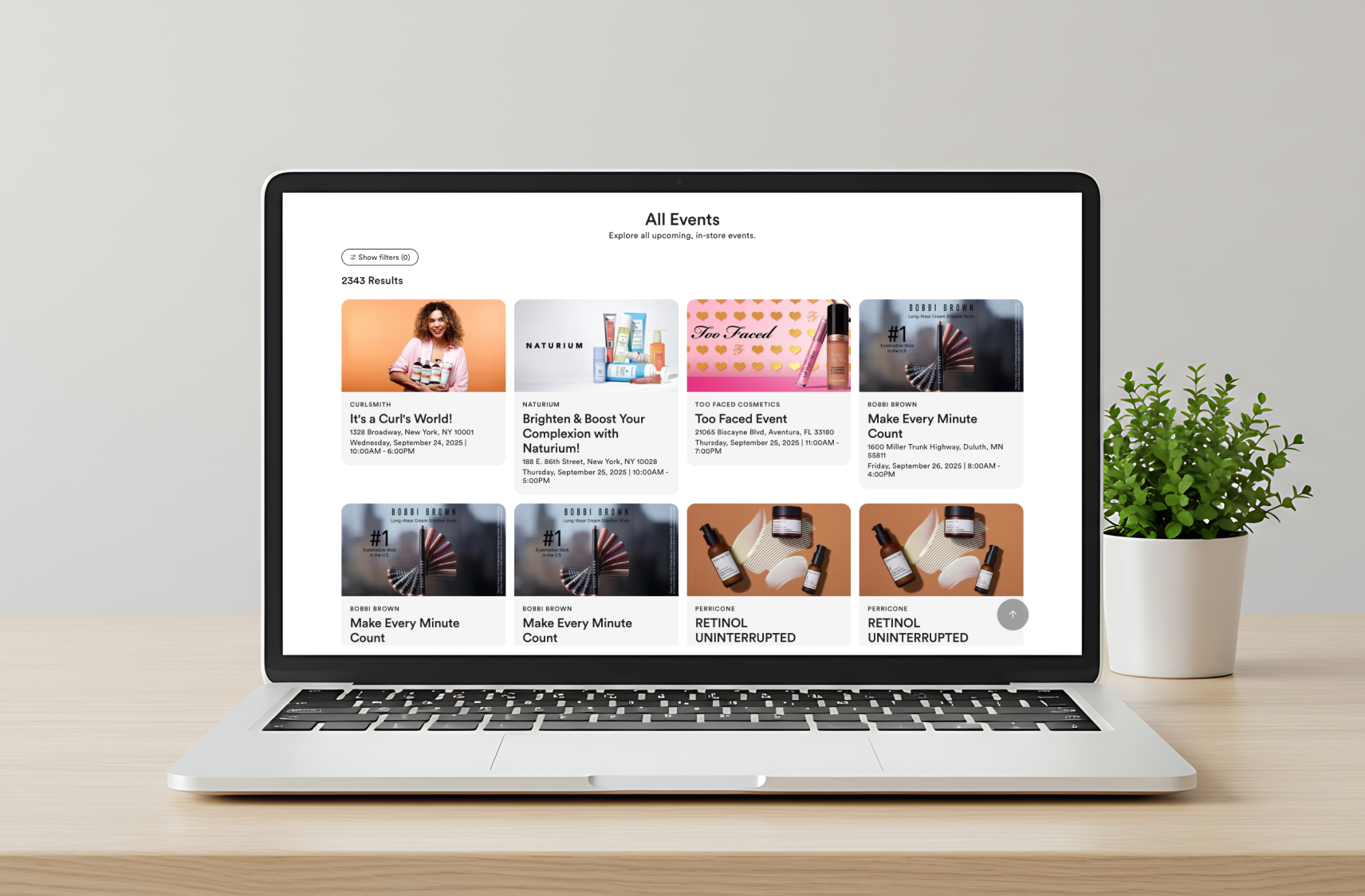

Shaping the future of Ulta Events through UXRIBM Consulting

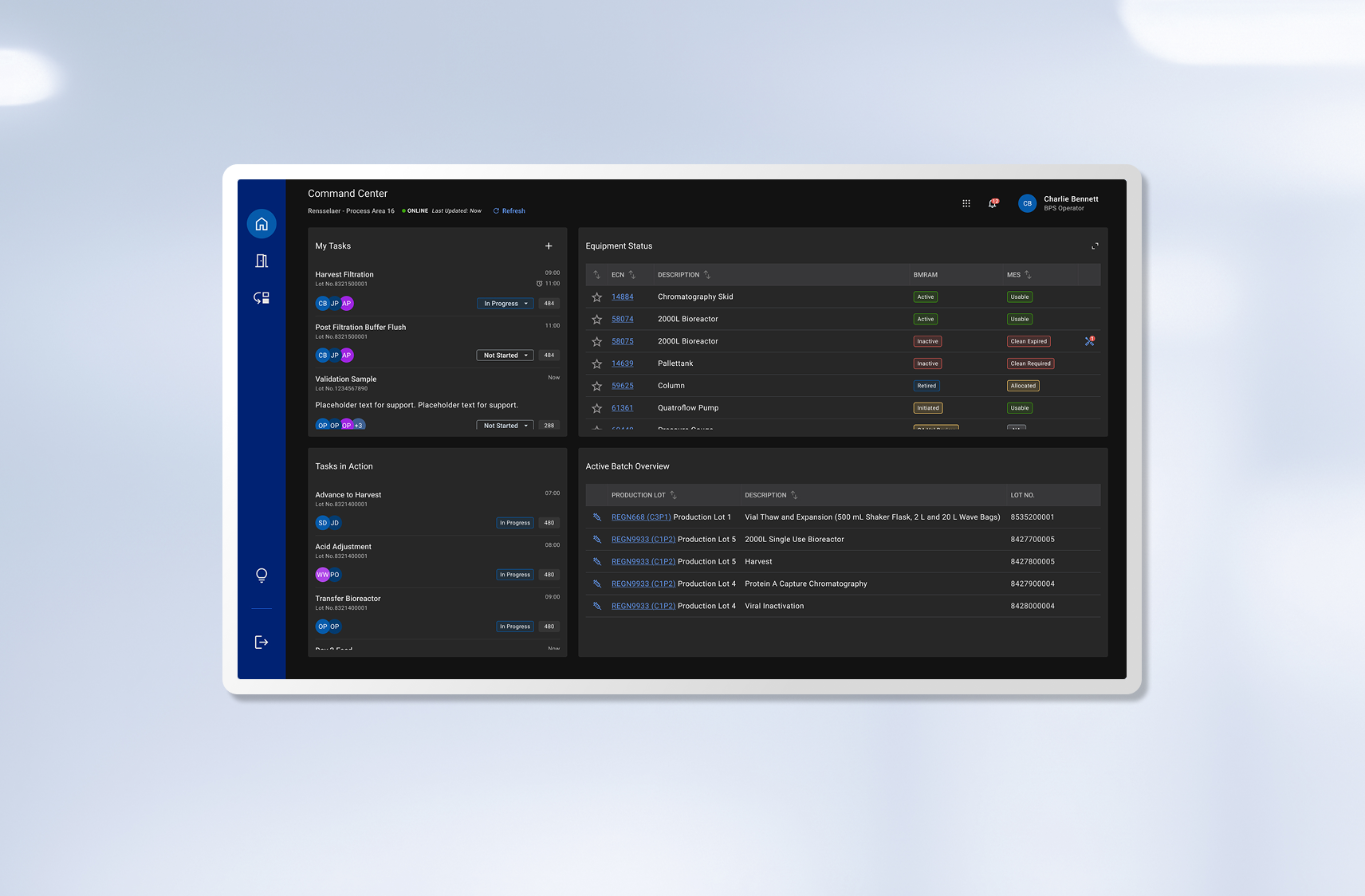

Building a custom tool for manufacturing operationsIBM Consulting

Modernizing a scheduling tool for pilotsProject type

Streamlining the candidate hiring experienceIBM Internship Project