Designing a unified application that transforms manufacturing efficiency

CLIENT

Confidential - Pharma

TYPE

Manufacturing 4.0

ROLE

UX Designer

FORM

Flutter App

DURATION

Oct '24 - Oct '25

INDUSTRY

Life Sciences

This project began with a 3-day Enterprise Design Thinking workshop, where the team aligned on key personas, identified pain points, developed need statements, and defined critical use cases. By the end of the workshop, we had collaboratively storyboarded the foundation of the application.

Following the workshop, design held weekly sessions with the project owner team to refine and prioritize features, define new requirements, and continuously enhance the existing design.

Multiple disparate systems and miscommunication were costing operators nearly 200 hours each year

Current state, Bioproduction Specialists (BPS) rely on multiple disconnected systems, manual approvals, and email-based task coordination to complete their work leading to numerous inefficiencies.

Our challenge: design an intuitive tool that integrates key enterprise systems to achieve data centralization, streamlined communication, and less operational inefficiencies.

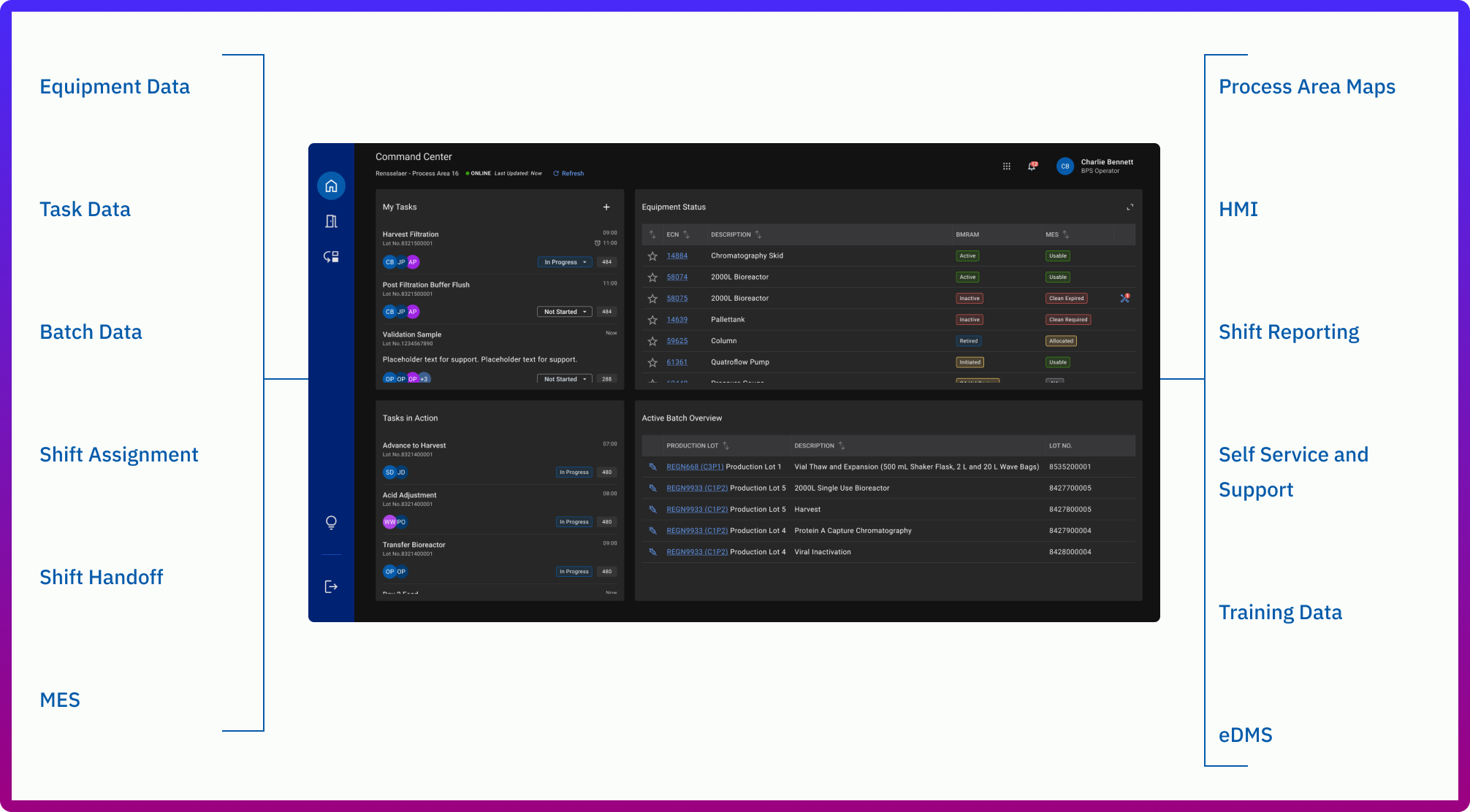

Final design homepage with a list of integrated data (not comprehensive)

Our discovery workshop with end users revealed 4 main pain points driving inefficiency

Activities conducted included empathy mapping, pain point prioritization, and future state storyboarding.

Addressing these pain points showed potential for Manufacturing to save 54,000 annual hours through real-time equipment monitoring, centralized task assignment, integrated systems, and democratized information access.

Screenshot of workshop activities

North star themes guided a design that centralized data and simplified workflows

From the workshop insights, we defined our guiding principles: communication, interconnectivity, automation, relevant visibility, and trust. These themes shaped the design of the final product.

As a result of the workshop, these prioritized pillars act as our north star when designing the future state experience

Projected impact and expected outcome: hundreds of hours saved and significant deadtime reduction

ROVi has not yet been deployed to active process areas but projected benefits include:

- Significant annual hours saved through reduced manual approvals and faster data access

- Shortened response times for equipment issues

- Increased operational transparency across teams

- Reduction of production deadtime through streamlined workflows

- Measurable improvements in accountability, communication clarity, and real-time decision-making

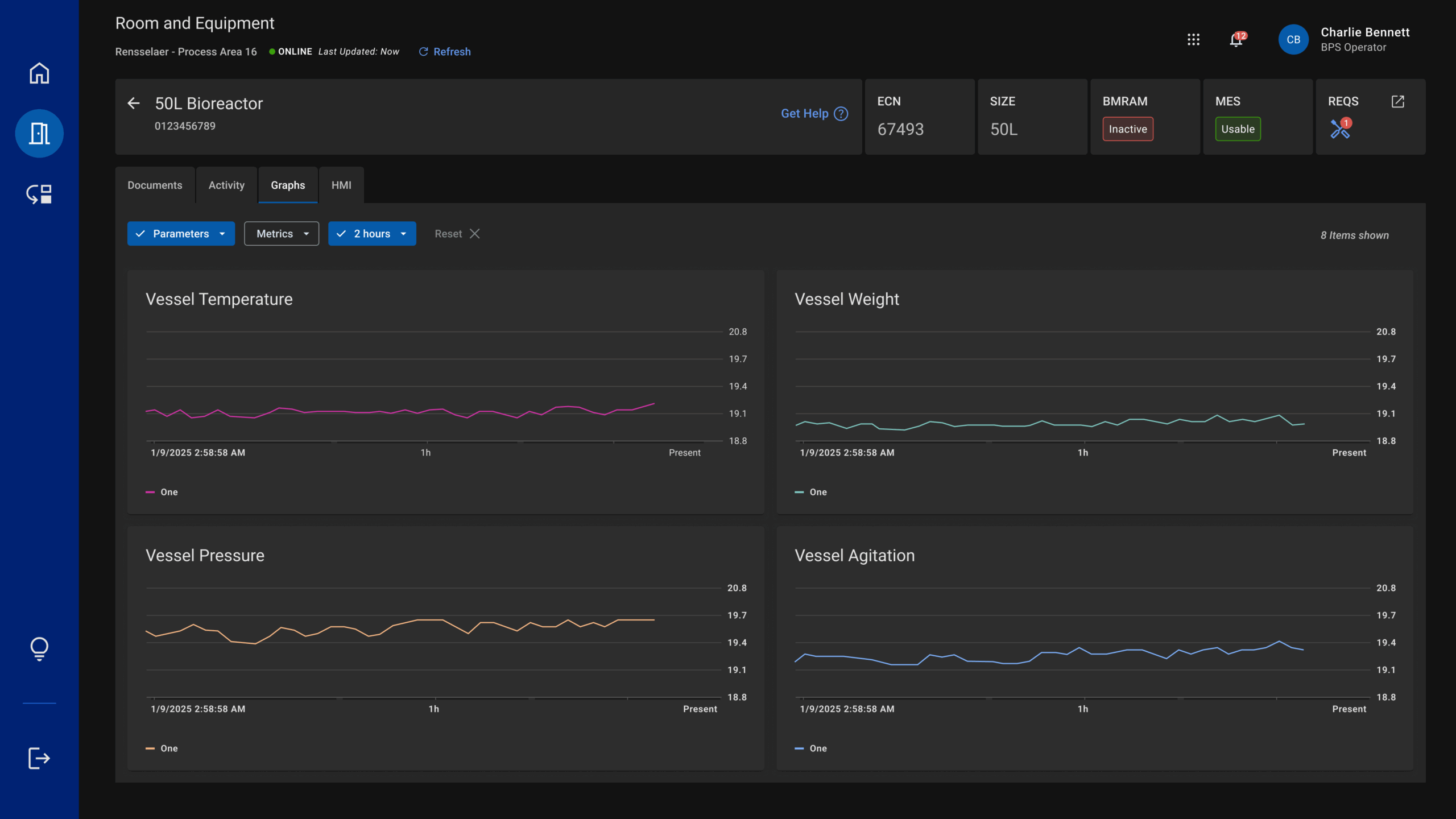

The Command Center is is estimated to save at least ~814 annual hours by enabling real-time monitoring and accelerated troubleshooting.

Value adds within the Command Center include relevant visibility for all types of tasks, insight into batch statuses, and real-time equipment tracking. By eliminating the need to search across multiple systems, we enabled operators to respond faster and make informed decisions without workflow interruptions.

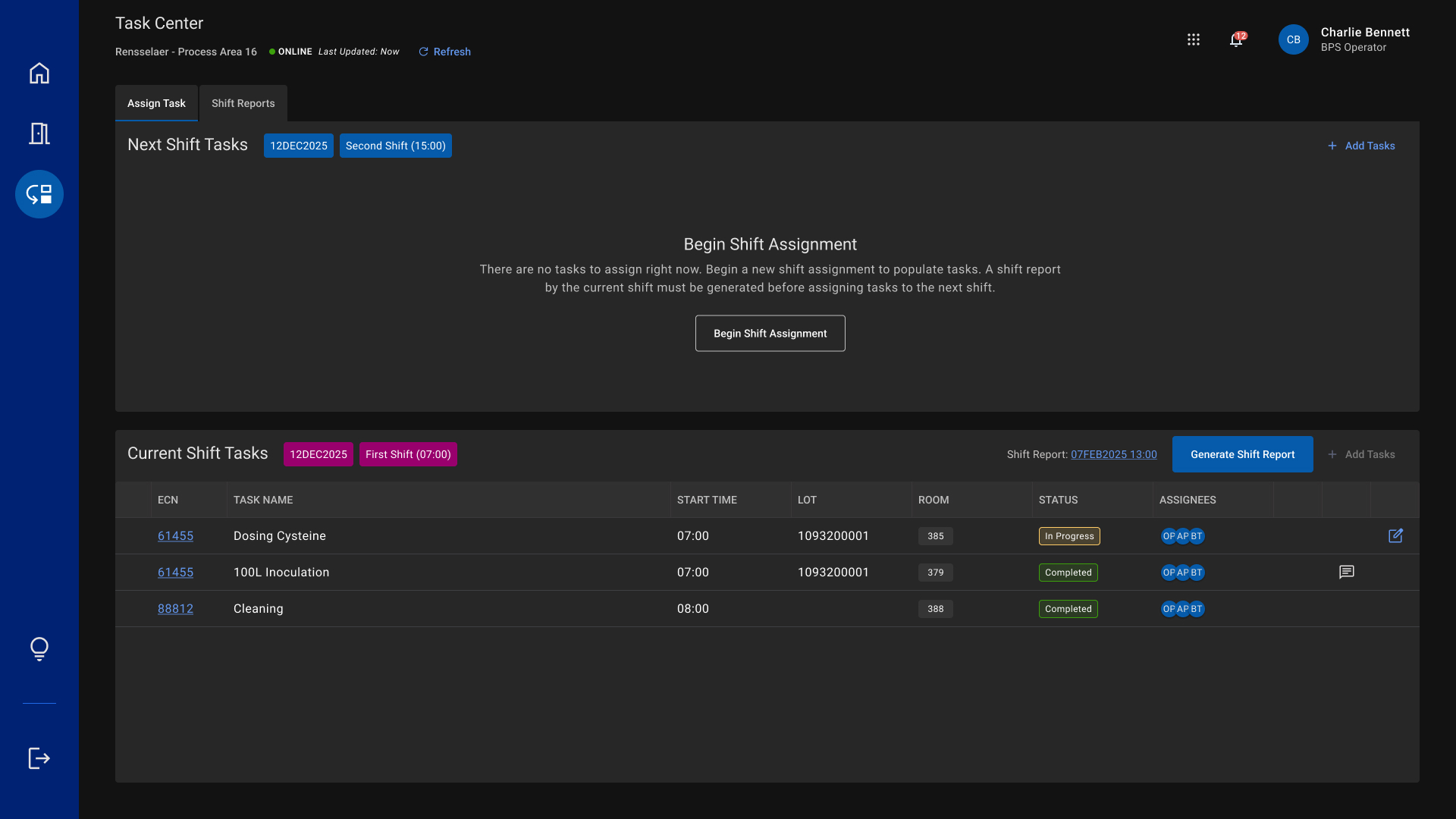

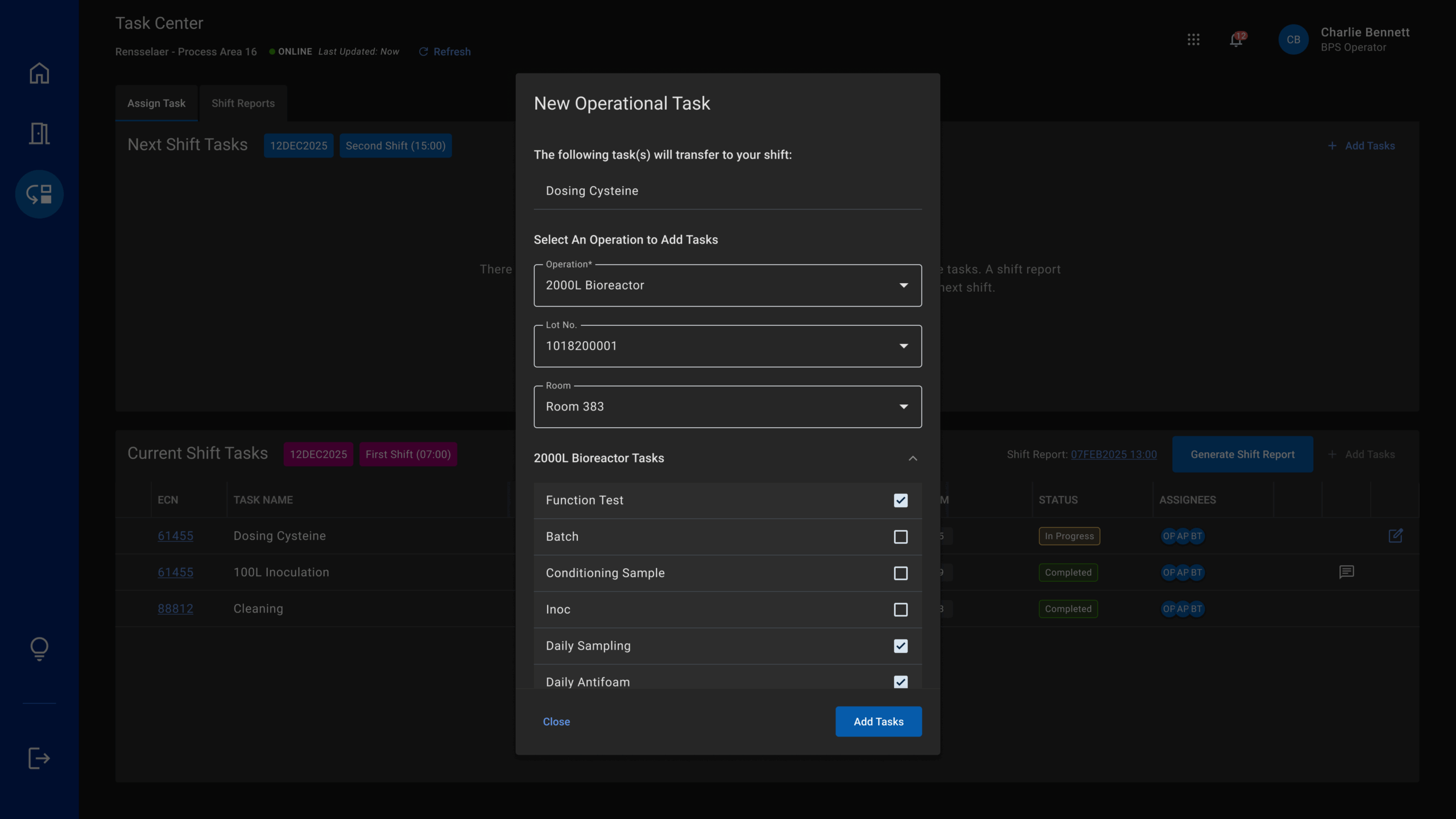

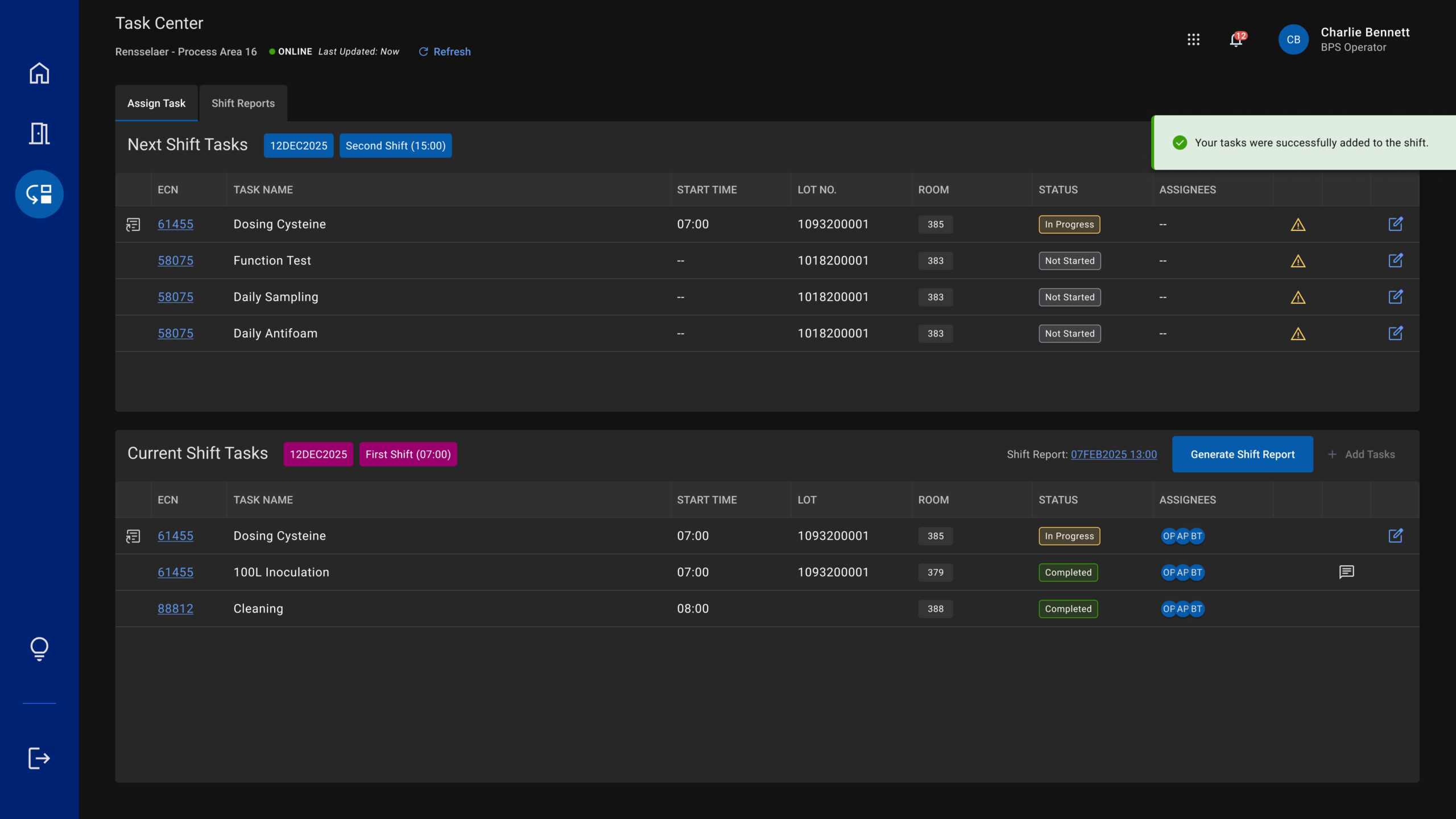

The Task Center replaces email-based handoffs, saving ~867 annual hours.

Through automation and minimal lead input, all things regarding shift assignments, task assignments, and shift reporting can be done through the Task Center.

![Room & Equipment [Portable]](https://www.sarahyduenas.com/wp-content/uploads/2025/10/Room-Equipment-Portable.jpg)

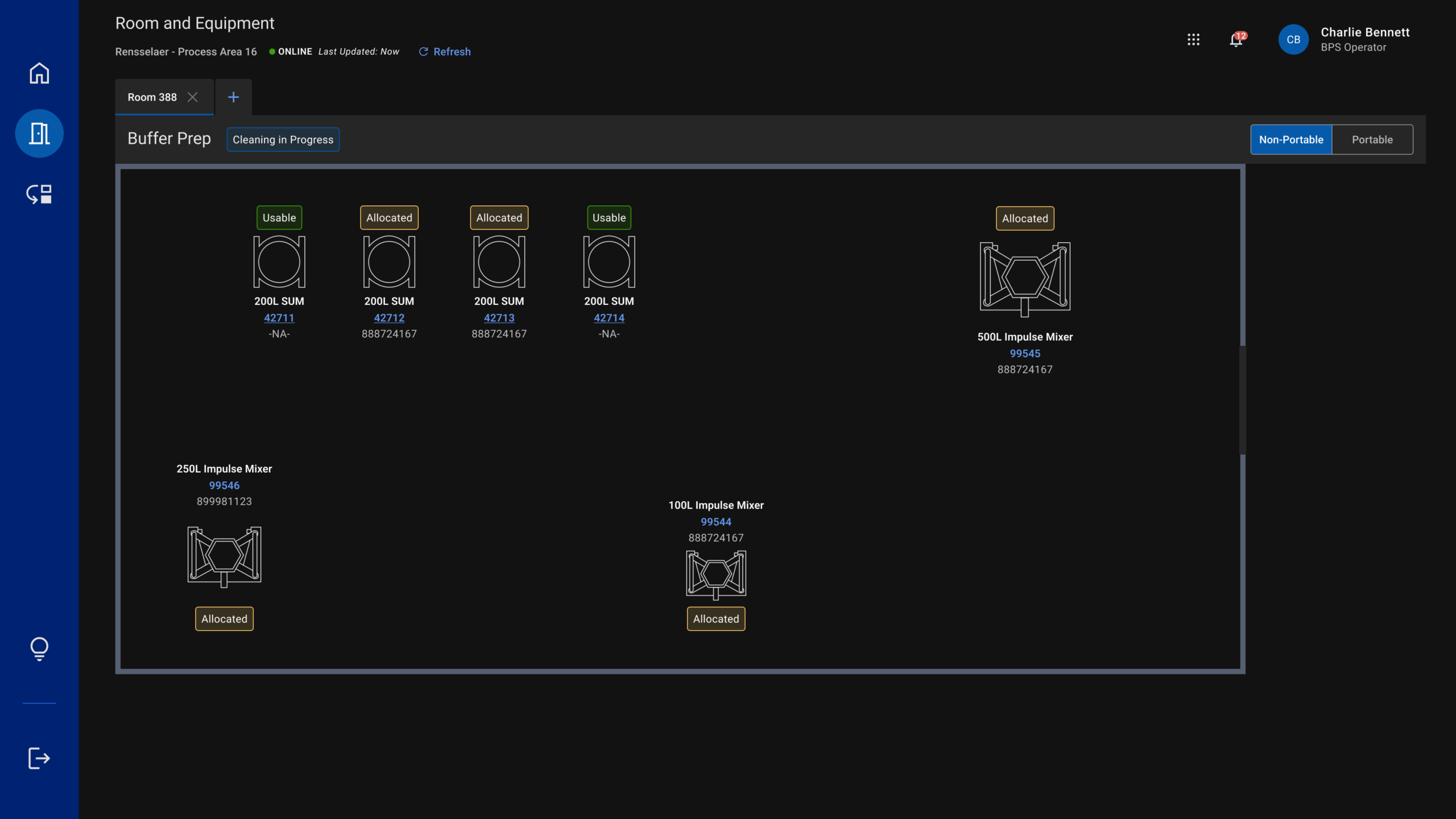

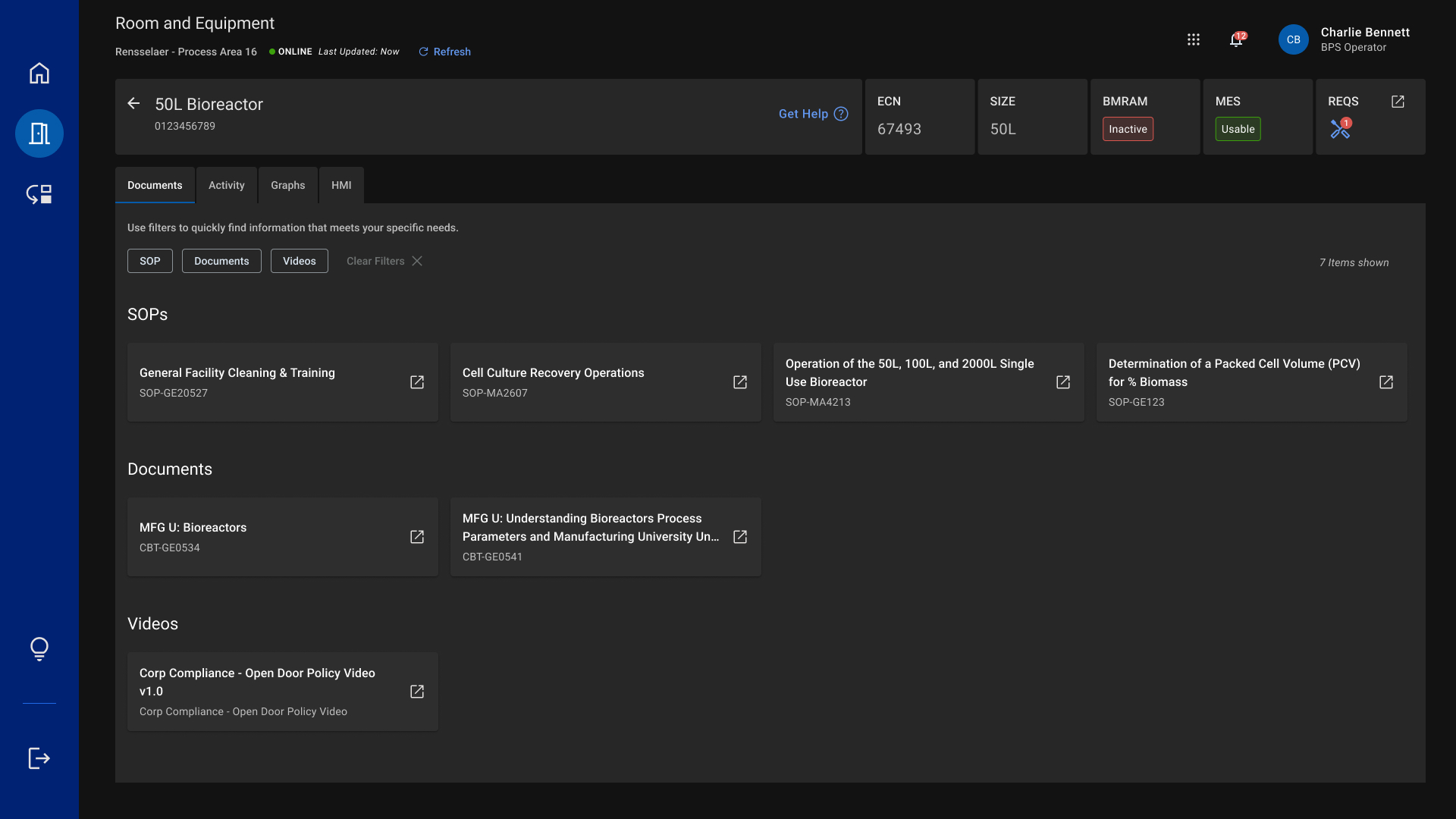

The Room & Equipment pages enable users access to real-time equipment statuses, documents, and data.

What could once be done only through multiple disparate systems and physically going into process areas, can now be done through the Room & Equipment pages.

My Role

As UX designer, I translated insights and end-user knowledge into design screens. This was done through weekly sessions with the PO team to uncover net features and iterate on exisiting features. I maintained the design system and kept a comprehensive prototype of the app for demos. This could not have been done without partnering architects and developers to solve API and integration challenges alongside the rest of the team. Lastly, I conducted front-end testing, logging findings in JIRA to ensure quality.

Take a look at my other projects 𓀙

Designing a tool to enhance production operationsIBM Consulting

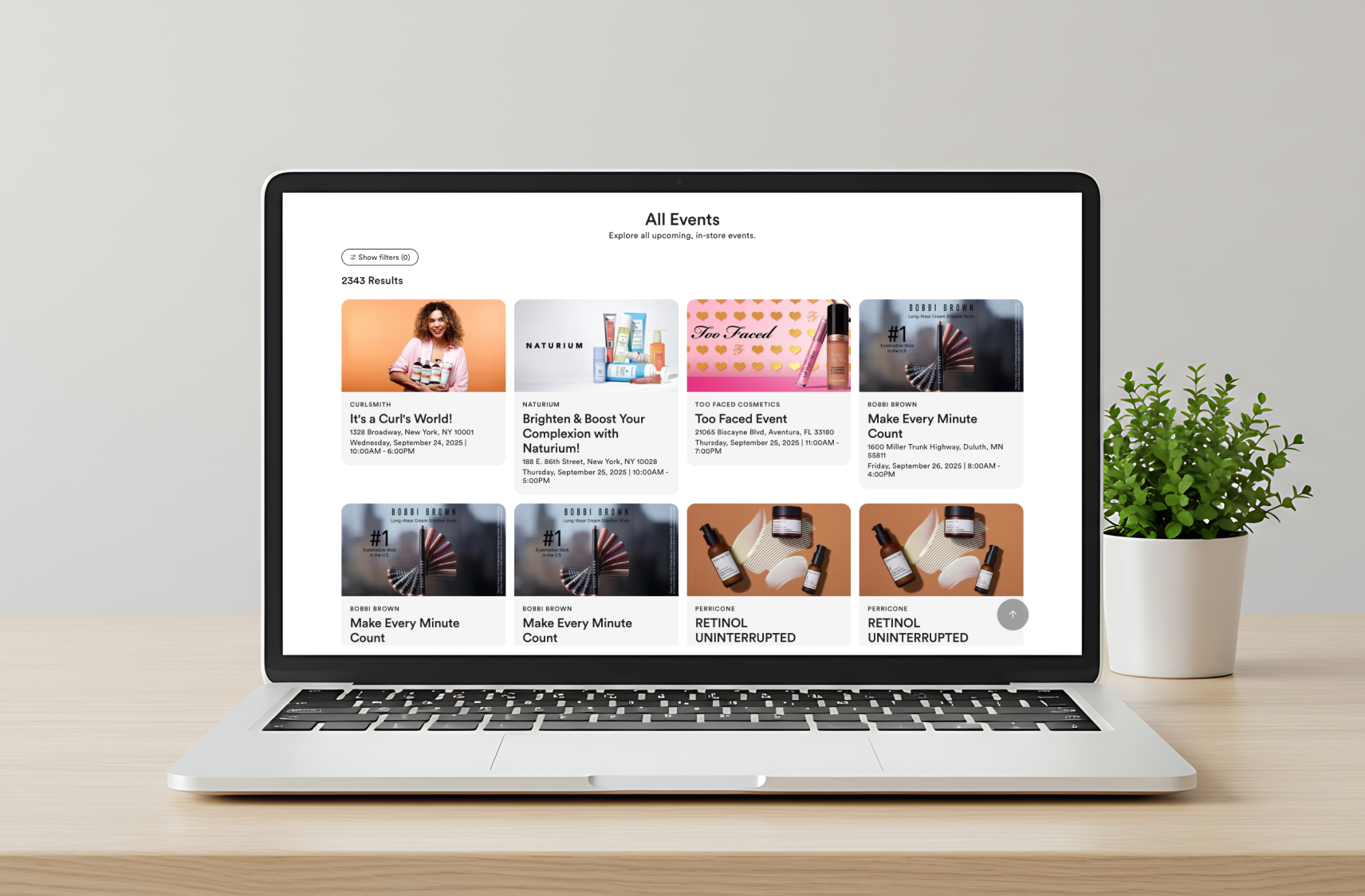

Shaping the future of Ulta Events through UXRIBM Consulting

Modernizing a scheduling tool for pilotsProject type

Streamlining the candidate hiring experienceIBM Internship Project